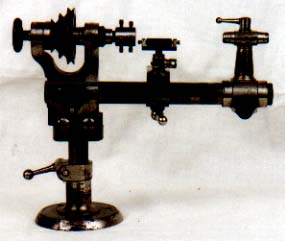

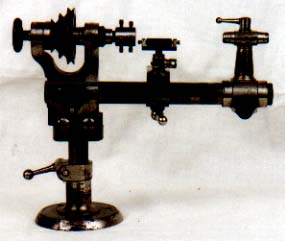

In this first lesson you're going to learn the very basics of turning for the clock & watchmaker on what can be the most valuable tool in the shop when you know how to use it properly, that's the 8mm jewelers or watchmakers lathe. Even though this machine's capable of doing just about any turning job you'll come across in the shop it's usually found sitting in a corner somewhere, and if it's ever used it's just for something simple like polishing parts. Well I want to tell you now that it's really not the owners fault if this machine's just sitting collecting dust. Even though it's an extremely capable, versatile machine it's just about useless if you don't master the few simple basic techniques that you'll need to run it.

Back when watch and clock makers went through a formal training course or apprenticeship they were required to practice these basics and became proficient at turning common parts very quickly. When they finally graduated and opened their own shops they would spend a very large portion of their start-up capitol on the lathe which was thought to be the most important tool in the shop. They used it a lot because they knew what it was capable of doing and how to do it.

Well the majority of these watch and clock makers have retired from the trade and have left behind many of these lathes which are available at a fraction of the cost of a new machine just waiting to be put back in use. The problem is that there aren't many people around any longer to teach how they're used. Well, that's what you're going to do in this video. You're going to cover the use of hand gravers until you actually learn to "feel" the metal being machined. That feel means a lot of things. It's something you'll acquire through a little practice. It's knowing what speed is best for a given hardness or type of metal, knowing how much pressure to apply with your graver and a lot of other little things, without ever having to think about it. Kind of like driving a car. Once you've learned the basics it becomes second nature, but try driving without knowing where the brakes are or what the steering wheel's for and you're probably going to get discouraged and park the thing somewhere to collect dust too. Well there's absolutely no better way to acquire that "feel" than to learn with hand gravers first and absolutely nothing as important as acquiring that "feel" if you plan on moving onto other types of lathes with cross slides or really any other type of machining, get this under your belt and the rest will come naturally. You'll automatically adjust the graver for things like positive or negative rake just by tilting it a little in your hand without thinking about it, then when you start using cross slides with toolbits you'll know exactly what bit to use, at which angle and just how fast to feed it across the metal. It will "feel" natural. Other types of lathes with compound slides and toolholders certainly have their place in the shop but as a machinist and toolmaker I can tell you that many turning jobs you'll encounter in a clock or watch shop can be set up in the 8mm lathe, machined with a hand graver, removed and possibly even replaced in the clock or watch in less time than it takes to even set-up one of these other machines.

You'll see how simple yet valuable these machines really are when you learn a few little secrets on how to use hand gravers.

This video is the first of a series of lathe videos and covers what I feel is the most important subject matter that a person can learn if he or she plans on doing advanced turning, pivoting, milling and gear cutting in the future and that's Learning The Basics First!!.

1 hour and 40 minutes of non-stop instruction. Extremely high quality 3 chip digital video cameras and digital editing makes this video super clear, clean and professional.

Check Out This Past Newsletter Covering Lathes

Lathe Newsletter

Check Out This Past Newsletter Covering Lathes

Lathe Newsletter

Click to Watch some

Click to Watch some

Streaming Video Clips

of our courses.

Home Page

Copyright: Tascione 1995-2010 Questions? Email Bob

Click to Watch some

Click to Watch some